Fire Rated & Insulated Wall Panels

Isowall®

ISOWALL® insulated wall panel systems consist of a rigid EPS (Expanded PolyStyrene) foam core with laminated sheet steel permanently bonded to both sides. A finished ISOWALL® building, ceiling or partition wall provides a strong and reliable thermal performance system that can be installed quickly and easily by almost anyone.

ISOWALL® Insulated WALL PANELS

ISOWALL® panels are energy efficient and feature an aesthetic profile that will look good for years to come. From small coolers to large commercial buildings, soffits to demising walls, ceilings to partitions, ISOWALL® insulated wall panel systems provide the ideal energy-efficient and economical continuous insulation solution for any building project.

46”

Width

4.1

R-Value

2″ – 10″

Core Thickness

300db

Acoustics

Downloads &

Links

ISOWALL® Applications

Key Features & Benefits

Superior Insulation

- R-value is 4.1 per inch and it doesn’t deplete over time

- Core thicknesses range from 2″ to 10″

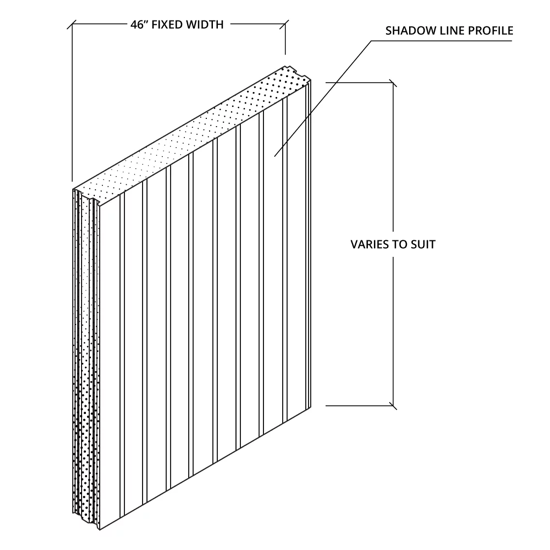

- Width is fixed at 46” (3.9’)

Clean Finish

- The finish can be either smooth or embossed

- The profile can be smooth, Shadowline or micro rib

- Available in a variety of standard colours

- CFIA acceptance for sanitary room requirements

- Mold and mildew resistant

Easy to Install

- Lengths can be custom-tailored to fit nearly any workable height

- Trims, flashings, angles and other accessories can be provided to complete a standard installation

- Tongue-and-groove edges provide a snug, secure fit

- Panels can be custom-tailored/field cut to accommodate windows, doors, ventilation, piping, fans, etc.

- Harmonious transition between ISOWALL® and ROCKWALL™ panels (when required)

Quality Materials

- Stressed skin, sandwich panel design

- Metal facings permanently bonded to an expanded polystyrene (EPS) core

- Uses a heat polymerizing adhesive for secure bonding

- Produced in a continuous in-line method to ensure optimum uniformity and quality

- Both the top and bottom are made from 26 gauge pre-painted and profiled galvanized steel

- Steel facings are roll-formed and mechanically bonded with a thermosetting adhesive to the EPS core

Try It Out First

Our ISOWALL® insulated wall panel product speaks for itself. Try a sample.

Superior Insulation

- R-value is 4.1 per inch, and it doesn’t deplete over time

- Core thicknesses range from 2.5″ to 10″

- Width is fixed at 46” (3.9’)

Easy to Install

- Lengths can be custom-tailored to fit nearly any workable height

- Trims, flashings, angles and other accessories can be provided to complete a standard installation

- Tongue-and-groove edges provide a snug, secure fit

- Panels can be custom-tailored/field cut to accommodate windows, doors, ventilation, piping, fans, etc.

- Provides a harmonious transition between ISOWALL® and ROCKWALL™ panels (when required)

Clean Finish

- The finish can be either smooth or embossed

- The profile can be smooth, Shadowline or micro rib

- Available in a variety of standard colours

- CFIA acceptance for sanitary room requirements

- Resistant to mold and mildew

Looking For Better Insulation Or Water Protection?

Are you looking for better fire protection or water protection? Check out ROCKWALL™ fire rated wall panels and QUICKLINER™ PVC plastic panels. They’re a great add-on where ISOWALL® isn’t what you need!

Where Can You Use

ISOWALL® Insulated Wall Panels

From small coolers to large commercial buildings, soffits to demising walls, ceilings to partitions, ISOWALL® insulated wall panel systems provide the ideal energy-efficient and economical continuous insulation solution for any building project.

Benefits of

ISOWALL® Insulated Wall Panels

Easy To Clean

Our wall panels are easy to clean and don’t support mold in the first place.

Insulated

ISOWALL® has a 4.1 per inch R-value and it doesn’t deplete over time.

Built To Last

Once installed the panels are maintenance-free and have long building lifecycles.

Clean and Safe

The panels have CFIA acceptance for sanitary room requirements.

Easy To Install

Installation process can cut construction costs in half. We offer custom fabricated wall and ceiling building solutions in lengths of any transportable length.

Hygienic

ISOWALL® panels meet the strict sanitation standards set by the CFIA and are resistant to mold and mildew.

Sustainable

ISOWALL® panels are a stressed skin, sandwich panel with metal facings permanently bonded to expanded polystyrene (EPS) core with a heat polymerizing adhesive.

Cost Savings

The panels have a high thermal barrier with vapour resistance resulting in significant energy saving R-value (R4 per inch) for consistent thermal performance and thermal envelope. Energy cost savings of as much as 30% over traditional multi-part building systems.

Chemical Resistance

Our plastic panels are inert to most mineral acids, bases, salts & paraffin-hydrocarbon solutions.

Start the Conversation

Tell us about your project and we can give you all the details you need about how ISOWALL® insulated wall panels can improve quality and save money.

ISOWALL® Specifications and Details

Product Superiority

Superior materials and manufacturing

ISOWALL® panels are a stressed skin, sandwich panel with metal facings permanently bonded to expanded polystyrene (EPS) core with a heat polymerizing adhesive. The panels are produced in a continuous in-line method for optimum uniformity and quality. The steel top and bottom are 26 gauge pre-painted and profiled galvanized steel facings that are roll-formed and bonded mechanically with thermosetting adhesive to an EPS core.

Strong and moisture resistant

The core material is lightweight yet dimensionally stable, with high thermal performance and moisture resistance.

Easy to Install

A tongue and grove interlocking edge is designed in both the core and the metal facing, producing an easy to install joint that is water-tight. Optional sealant can be applied during installation. Panels are 46 inches (3.9′) wide and cut in custom lengths as required for your specific building project. ISOWALL® and ROCKWALL™ panels have similar facings and joint treatment so they can be used together when appropriate.

How Does ISOWALL® Compare?

| Features | ISOWALL® | ROCKWALL™ | QUICKLINER™ | FRP |

|---|---|---|---|---|

| Composition | 26 ga. painted steel & Expanded Polystyrene (EPS) foam | 26 ga. prepainted steel & Rockwool mineral fibre | Polyvinyl chloride (PVC) | Fibre-Reinforced Plastic (FRP) |

| Standard Colour | White | White | White | White |

| Custom Colour | Special order | Special order | Special order | Special order |

| R-value | R-4.1 per inch | R-4.1 per inch | ✕ | ✕ |

| Food Grade | ✓ | ✓ | ✓ | ✓ |

| CFIA Accepted | ✓ | ✓ | ✓ | ✓ |

| Thicknesses | 2″ – 10″ | 2.5″ – 10″ | 3/8″ | 0.09″ |

| Finished widths | 46″ ea. | 46″ ea. | 18″ ea. | 48″ ea. |

| Manufactured lengths | 5′ – 40′ | 5′ – 30′ | 8′, 10′, 12′, 14′, 16′, 18′, 20′ | 8′, 9′, 10′, 12′ |

| Price | $$ | $$$ | $ | $ |

| Installation | Moderately easy | Specialty | Easy | Easy |

| Interior applications | ✓ | ✓ | ✓ | ✓ |

| Exterior applications | ✓ | ✓ | Limited | Limited |

| Ceiling applications | ✓ | ✓ | ✓ | ✓ |

| Wall applications | ✓ | ✓ | ✓ | ✓ |

| Self-supporting | ✓ | ✓ | ✕ | ✕ |

| Noncombustible | ✕ | ✓ | ✕ | ✕ |

| Fire-rated | ✕ | ✓ | ✕ | ✕ |

| Roof applications | ✕ | ✕ | ✕ | ✕ |

Ratings and Testing Data

ISOWALL® panels last as long as the service life of a typical commercial building. The durable insulation panels also reduce operational costs for energy and maintenance, and offer multiple end-of-life reuse options.

Materials

ASTM A653

Interior and exterior facings are CFIA accepted 0.18 min, G-90 hot dipped galvanized steel, conforming to ASTM A653-Grade 33 pre-coated with an imperial white standard finish.

Durability

Panels last as long as the service life of a typical commercial building and comply with various industry standards and building safety codes. Our durable panels also reduce operational costs for energy and maintenance and offer multiple end-of-life reuse options.

Flame Spread Test

ISOWALL® panels have been tested by NRC and meet Flame Spread Test in accordance with ULC S102, ULC c376-95, UL-5138 (Flame spread 25, smoke developed 290), Intertek NP-C463 for use in sprinklered buildings. Complies with CAN/ULC S102.

Weight

The steel skins on ISOWALL® insulated wall panel systems contain a substantial amount of recaptured metal and are low-weight material to reduce transport and installation energy.

Ready to try ISOWALL® Insulated Wall Panels?

Call Us To Learn More